Well, that wasn’t the year any of us expected! Yet, in many cases, it saw remarkable successes in incredible circumstances. The pandemic didn’t completely alter our technology strategies. It accelerated them – especially the drive toward digital transformation, according to McKinsey. So, what does the year ahead hold?

Cloud is the foundation of digital transformation…

According to Forbes, manufacturers will spend as much as a third of their IT budget on the cloud in 2021. It’s not difficult to see why. COVID-19 exposed the difficulty of quickly and effectively introducing new working practices and business models based on legacy, on-premise systems. As we (hopefully) enter a post-COVID recovery phase, many of the enabling technologies – such as automation, IoT, and teleworking – will rely on a sound cloud infrastructure. It will be the basis on which increased collaboration and innovation is cost-effectively built.

…but it’s not alone!

The 5G revolution is finally upon us and 2021 is likely to be the year we see its influence in manufacturing. Expect 5G to become a key enabler of Industry 4.0. Up to 100 times faster than 4G, it offers dramatically reduced latency to share data quickly and speed processing. It has the potential to deliver leading edge capabilities into smaller or remote facilities within the need for major infrastructure investments. In addition, it facilitates the move towards edge computing that will bring processing and insight closer to the end-user.

Remote working is the new normal

Perhaps the biggest change that happened in manufacturing last year was the rapid pivot to remote and home working – and it’s here to stay. What started as necessity quickly delivered benefits in terms of increased productivity and reduced costs. Going forward, Forrester suggests most companies will employ “anywhere-plus-office hybrid” models in which more people will work remotely more often. However, the pandemic exposed gaps in manufacturers’ ability for digital collaboration and knowledge sharing. Investment in secure information management platforms will increase to meet this demand.

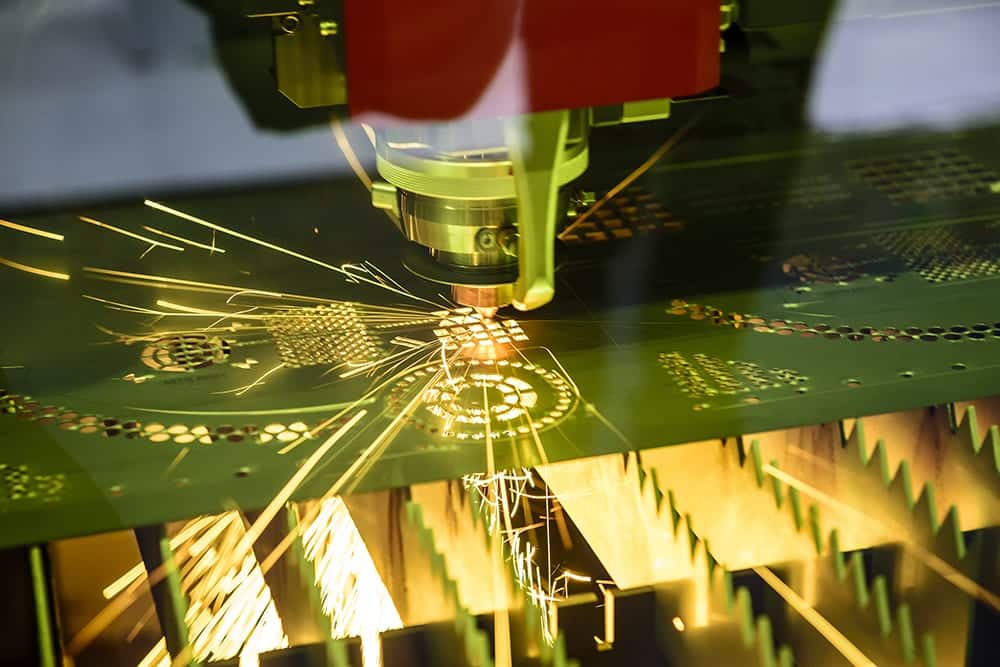

Automation comes to the fore

With a focus on revenues, automation will be a key driver for IT investment in 2021. The automation of manufacturing tasks increases employee productivity, frees staff to higher value activities and provides the basis for unattended operation where more workers are off-site. This is true at both a physical and process level. At a physical level, increased human and robot collaboration looks to be the way forward. ABI expects global cobot revenue to increase at a 49 percent compound annual growth rate through 2025. It’s the basis for teleoperation where employees are able to control and manage equipment and assets remotely.

Adaptability, resilience and sustainability drive the new supply chain

COVID-19 exposed the risk for manufacturers in their current supply chains. Manufacturers – and especially those with complex, global supply chains – must be able to quickly adapt to handle major disruption. This will accelerate the trend towards the adoption of cloud-based supply chain platforms that enable flexible and scalable ways to trade, collaborate and grow digital partner ecosystems. However, there is another trend that will influence supply chain development this year – sustainability. Forrester says: “Fair trade, labor conditions, or sustainability … have become vital elements of manufacturers’ brand value”. The firm predicts this will be a trend for core manufacturing sectors in 2021.

Accelerating digital experience puts more focus on data

In response to the pandemic, manufacturers – especially in automotive – have increased their reliance on digital channels to connect and engage customers and partners. According to CarGurus, 61% of car buyers are now open to buying online—almost twice as many as before the pandemic. This places a major focus on digital experience (DX) for all manufacturers – and that requires the ability to gain value and insight from customer data. COVID-19 has further emphasized the importance of understanding demand signals and addressing customer concerns in order to assess unmet needs. In turn, transformative activities like using multiple sources of customer data will be imperative to understanding new challenges consumers are facing as we enter 2021.

As ever, security is vital

According to Security Brief, the majority of industrial organizations face increase cyber threats since COVID-19. Yet, Bain has found that less than a quarter of companies are actually prepared for new types of cyber attack. Deloitte suggest the increase in digitization, automation and IoT will be important drivers for cyber security in 2021. To this, we have to add the threat from 5G, which has the potential to render many traditional protections virtually redundant. Manufacturers will focus on building cyber resilience by taking an identity-centric approach to managing access for the people, systems and things on their networks.

To find out more about the range of digital solutions from OpenText for manufacturing, visit our website.